PROFILE

ROTAR GROUP

Overview

Located in Ta Li Industrial Park on the northwest suburb of Taichung City, Rotar Machinery Industrial Co., Ltd. (ROTAR GROUP) occupies a total area of 31,500 m², with packaging lines and storage warehouse occupy a total area of 22,000 m². Currently possessing three production plants made up of more than ten different specialized departments. ROTAR GROUP is one of the well-known significant organizations successfully transforming from a traditional professional manufacturer to an international corporation among the industry.

VIBRATORY SURFACE FINISH PRODUCTION PLANT

Established in May 1981, ROTAR Vibratory Surface Finishing Center is now the largest processing plant in Southeastern Asia by equipping over 200 machines to operate over 150 tons daily capacity. The workpieces include a wide range of hand tool components, hardware components, machine components, forged and cast workpieces, alloy and etc.

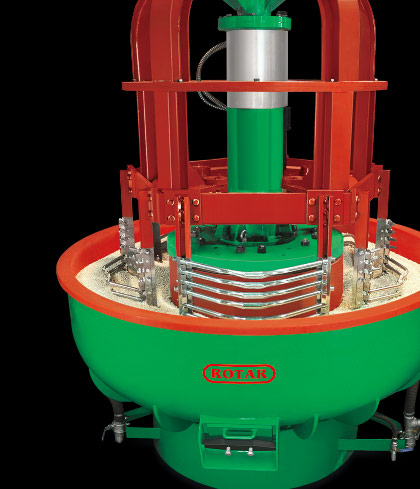

MACHINERY PRODUCTION PLANT

Based on the direction of constantly improving design and production, ROTAR put efforts in developing various surface abrasive machines by breaking through the traditional vibratory processing technology. In 1993, ROTAR was the first company in Taiwan vibratory finishing machinery field to be approved by ISO-9002 certificate.Currently, ROTAR not only possesses various patents and certifications worldwide but also recognized to be the icon & pioneer in the top filed of vibratory finishing machines.

TOOL PRODUCTION PLANT

Possessing ROTAR outstanding hand tools surface finishing technology and after a long period of study and research in the tool production industry, the organization decided to launch a new tool production line in 1994. The product line includes various types of wrenches, sockets and all kinds of different professional tools. Up to present, the production line is able to generate a manufacturing capacity of more than 15,000,000pcs per year through OBM/ODM/OEM cooperation. ROTAR is now also to be considered one of the best tool manufacturers in the professional tool field in Taiwan.

Service

The meticulous customer service system of ROTAR three core businesses solves various problems in professional vibratory processing and hand tools, and also provides a complete quality guarantee to customers.

CUSTOMER SERVICE

- Application Consulting

- Q&A

COMPLETE TECHNICAL SERVICE

- Product Research & Development

- Sample Test & Treatment

- Factory Equipment Planning

AFTER SALES SERVICE

- Customer Questionnaire

- Maintenance Contract

- Technical Support

- Product Warranty

QUALITY ASSURANCE

Four primary quality principals of ROTAR GROUP are that "Unremitting pursuit of zero-defect", "Product standardization", "On-time delivery" and "Market internationalization" Products made and sold by ROTAR GROUP as well as services provided by the company shall meet the expectations of customers through constant technology improvement and conform to the international standards.

"We have always known that we are manufacturing quality products by using sophisticate expert manufacturing know-how and being insistent in attaining every requirement of high quality, "stated Mr. Chiao Wei, president and CEO of ROTAR GROUP.

Having established the complete quality management system, ROTAR GROUP is accredited ISO 9001 certification from both England Royal UKAS.. ROTAR GROUP sets International ISO Standard and various industrial product standards as quality management standards, and exerts great effort in internal quality management and quality cost. Being customers-oriented, ROTAR GROUP constantly attaches great importance to information from customers, and takes solving complaints of customers as an important step for quality improvement.

FUTURE EXPECTATION

In the past 40 years since ROTAR GROUP was founded, the company has

successfully developed and entered the international market.

However, the organization must constantly to be

reviewed and improved by reinforcing its enterprise ability in terms of internal management and productivity.

The board of the company fully understands that to reach a long-tem goal of sustainable development, the

organization must continue to integrate product and technology innovation together with human resources

improvement and expertise.

For this reason, ROTAR GROUP has adapted three main principles to guide the

future:

VERTICAL DEVELOPMENT

Facing a great global market competition, the company must set up a firm foundation before gaining the success. ROTAR GROUP is following a vertical development strategy to increase productivity, reduce production cost, and increase price competitiveness and market share by developing new production lines and manufacturing equipment and technology.

CONTINUOUS INNOVATION

The popularization of the internet and smooth communication has opened a wide range of business opportunities. Maintaining a competitive advantage will be a main issue for every company to manage and that also makes ROTAR GROUP unique and carries the company forward as the world around it changes. ROTAR GROUP is continuing to invest in innovative manufacturing procedures and technologies as well as the new product research and development. The management team understands that these new technology and product development will be ing the markets in the very near future.

EMPLOYEE AND CUSTOMER RECOGNIZATION

The success of ROTAR GROUP comes from the great efforts of employees within the organization and the tremendous supports of international customers. The company expects to continue to better reward this professionalism of employees by providing incentive programs, retirement funds, international travel opportunities and stock purchase in the future. And for rewarding all the royal customers, ROTAR GROUP plans to continue its dedication to high quality products, competitive price, punctual delivery and expert service. The company will constantly strive to be the best working partner and employer.

Tool Trolley Manufacturer

Main Product: